Rod Canare (rtypec on rctech) has been doing a bunch of posts on his trip to Japan as North American Tamiya Series champ. It's a great group of posts, and while he was there for sedan racing, he makes a great point:

"When my number was called I took off from the and as soon as I hit the

first corner, followed by the chicane and left hand sweeper leading into

the infield, I knew I was in trouble. Over steer everywhere! The

track definately had grip and I felt that the tires worked fine, but the

body just affected handling so much that whatever mechanical traction

the chassis had became a moot point. As I struggled with the car for

the first half of the qualifier, the theme song from the Benny Hill show

started to play in my head. Additionally, thoughts of how frustrated

my performance so far has been, and how embarrasing this must be for not

only myself, but for those who wished me the best of luck, started to

cross my mind. Fortunately, or unfortunately, driving the car required

my undivided attention and I was able stop thinking about it and just

hustle it. A big part of racing is your frame of mind. Once the car is

on the track, you've got what you've got and nothing will change that

fact your stuck out there until your run is completed. You can't stop

to fix what's wrong and you can't over analyze things. Just do the best

you can and get the most out of what the car will give you. My car

was bad, my driving not much better, and I wrung it out for all that

it's worth. Afterwards, I was asked if my back was sore because I

carried that car lol. Unfortunately, lap times suffered tremendously.

Despite going faster with a time of 14.566, the top qualifier pulled

off a 14.170."

Full post

Thread

Very good insight on the mental end of racing, and also how to strategize when you are limited on time...

"For the second qualifier, I made no changes to the car but opted to use

the Audi R8 instead of the Ferrari that it would provide a little more

steering. My justification for this decision was that if it worked,

great. If it didn't, atleast I'll be going slow in style. In

hindsight, this may have screwed me over since quality track time was

paramount and every opportunity to get a good run in mattered. There

was no room to take one step forward and two steps back, which happened

to be the case with my setups and choice of bodies."

"I used the final practice session as an installation run with the

freshly rebuilt car and a new setup. I focused on getting a feel for

the car and work on getting more of a feel for the track, all in three

minutes. With the new parts and settings, my car did something that it

hasn't done all weekend so far, it was squeeling tires! I've got

traction and the car was predicatable. I wished our practice sessions

were longer, I really needed the track time to figure out how to drive.

After three minutes, I was a bit off pace. That was understandable

since I wasn't really driving that hard because I just wanted to get a

feel for things and save the car, without having to do a post-wreck

trash'n dash repair job on a "freshy"."

Friday, December 14, 2012

Tuesday, December 4, 2012

A tire decal how to link

I found this neat link for a tutorial on how to apply tire logo decals permanently. Pretty cool.

http://www.rc10talk.com/viewtopic.php?f=37&t=27863

http://www.rc10talk.com/viewtopic.php?f=37&t=27863

Monday, November 19, 2012

Chatter about chatter

Does your car chatter?

This has been a reoccurring theme lately. The introduction of the Pit Shimizu and Tamiya "TCS" tires has been a good thing, but it's a lot different from foam tire racing, or even the older style Tamiya tires.

Many of the racers I talk to are concerned about their cars chatter/hopping. I get a little upset to see it myself. Typically, a car that chatters in the corners is having some sort of problem. Pan cars that chatter are worrisome for sure, but consider that we are in a situation which is not typical of pan cars. These cars now run heavy rubber tires, with a tremendous amount of grip. They are also narrow. Now add in a surface like carpet, and you're definitely looking at some hop. These cars are not smoothly getting into a drift angle like foam tire shod cars do. Everybody seems to want to cure this immediately since it's so disturbing.

Maybe it's a lot of worry about nothing.

I was thinking back to the 2010 TCS North American Finals. Danny Hua won the class and the trip to Japan, and I remember quite vividly seeing his car chatter the front end on the left side of the track. Like a lot of people who see this stuff now, I thought "Wow, his car chatters a lot" with a bit of concern. At the same time, he had a fast, race winning car. Could some chatter be the sign that your car is developing enough grip? It may be. I remember reading one of the late great Carroll Smith's full size racing books where he explained tire "judder" on full size formula cars. One thing that stuck with me was not only that it was at one point a big concern to the mechanics and engineers, but when they figured out WHY it was happening , they became less worried. It also turned out to be an indication that the driver had figured out how to get all the power down, and only the best drivers experienced the judder.

I'm not saying that a chattering car is a good thing, and obviously if the car is going nuts with the chatter, it's a negative. I just think that maybe some amount of chattering is probably part of the nature of rubber tires, especially on high traction circuits. To me, if the lap times are there, and the car is getting around the way you want it to, I don't think chattering is huge concern. If it can be cured I think that is a good thing, but I'm not sure some chatter is 100% bad.

This has been a reoccurring theme lately. The introduction of the Pit Shimizu and Tamiya "TCS" tires has been a good thing, but it's a lot different from foam tire racing, or even the older style Tamiya tires.

Many of the racers I talk to are concerned about their cars chatter/hopping. I get a little upset to see it myself. Typically, a car that chatters in the corners is having some sort of problem. Pan cars that chatter are worrisome for sure, but consider that we are in a situation which is not typical of pan cars. These cars now run heavy rubber tires, with a tremendous amount of grip. They are also narrow. Now add in a surface like carpet, and you're definitely looking at some hop. These cars are not smoothly getting into a drift angle like foam tire shod cars do. Everybody seems to want to cure this immediately since it's so disturbing.

Maybe it's a lot of worry about nothing.

I was thinking back to the 2010 TCS North American Finals. Danny Hua won the class and the trip to Japan, and I remember quite vividly seeing his car chatter the front end on the left side of the track. Like a lot of people who see this stuff now, I thought "Wow, his car chatters a lot" with a bit of concern. At the same time, he had a fast, race winning car. Could some chatter be the sign that your car is developing enough grip? It may be. I remember reading one of the late great Carroll Smith's full size racing books where he explained tire "judder" on full size formula cars. One thing that stuck with me was not only that it was at one point a big concern to the mechanics and engineers, but when they figured out WHY it was happening , they became less worried. It also turned out to be an indication that the driver had figured out how to get all the power down, and only the best drivers experienced the judder.

I'm not saying that a chattering car is a good thing, and obviously if the car is going nuts with the chatter, it's a negative. I just think that maybe some amount of chattering is probably part of the nature of rubber tires, especially on high traction circuits. To me, if the lap times are there, and the car is getting around the way you want it to, I don't think chattering is huge concern. If it can be cured I think that is a good thing, but I'm not sure some chatter is 100% bad.

Wednesday, November 14, 2012

Not gone, just underground...

It's been pretty quiet here on the F1.blog, but it's been busy. I've been trying to come to grips with a rubber tire setup for a TCS legal F104v2. So it's been a couple weeks of hiding in the under mountain secret lair/track trying to work it all out.

Anyway, I have been trying a of of things to get my car working consistently from session to session. I had some times where the car would be very fast, but then be no where near as good if conditions like temperature changed or traction went up or down due to car count. I also have been getting a lot of good suggestions and tips from friends and acquaintances. The big thing was to try to boil all this stuff down into something workable.

The big problem with this car being new, and a little unfamiliar, was that I did not have my "go to" adjustments figured out. Usually I have a few things that are sort of the big adjustments that will send your car in one direction or another and you know you've changed something. I had a bit of time where I felt like everything was vague and I was flailing a bit. I was trying to use both what I knew and the concepts I was learning from other people as well, and it was not meshing. So last weekend I decided to go back to the baseline to try to get my car working.

One thing I was pleased with was using a stiffer side spring. In the past I had run my Exotek car fairly stiff since it seemed to me the heavier rubber tires needed a stiffer car. I had recently began to try to make lighter springs work based on what I had seen with some of the on line setup sheets, and when the track was lower traction, it worked well. As soon as traction came up, it was not easy to drive, and in fact, somewhat unstable. It was still fast at times.

The problem with stiffer springs is that they can stabilize the car too much. The link car needs to roll a little to get around the corner, but there has to be a balance to be able to drive the car in a straight line. This is where the preload comes in. With the soft springs like Associated black or Tamiya pink/copper. you have to preload the spring a bit in a lot of cases to stabilize the car. With the softer springs, they really need to be set at just touching or even backed off the pod plate. This will dictate a lot on how the wraps the corner. With a really stiff spring, you can be backed of the pod plate so the car will rotate, but when the spring goes into compression, it will keep the car fairly flat. I think that a lot of the traction roll problems with these cars are generated from the rear of the car versus the front. This brings me to my next point, dampening.

I'm probably going to sound like a kook here, but I think that really heavy dampening is key. I had been up to 50,000 wt diff oil in the X1 damper tube, but I was wondering if maybe more could be better. After talking it over with one of my buddies who was endorsing massive amounts of dampening, I decided to go big. After some playing around, I settled on 120,000 wt Losi diff oil in the tube. This made the car much flatter, so much so that it would slide rather than traction roll. This again goes toward the theory that the much higher unsprung weight of the rubber tires requires the car to be a lot stiffer to control all that mass.

What really got the car working correctly with the higher dampening was a boatload of rear droop. I am now at 3mm over ride height. The droop seems to really give the car a lot of forward bite. I can get on the car pretty much where ever I want to. Previously, I was having to be a lot more careful with throttle inputs. Don't get me wrong, I find that smooth throttle input makes for very fast laps with F1 cars, but I feel a ton of confidence with the added bite.

At the same time, a minimal amount of front droop appears to better for me. I think it helps to keep the weight on the front tires under power to retain the on power steering. Steering feel is also less "floaty" and more direct. I had tried a lot of front droop, but I started migrating back to a minimal front droop setup, and I prefer it.

Another thing I had tried was a very horizontal shock. Usually this does produce a lot of on power steering at the expense of rear stability in my experience, but I'm not 100% sure about that now. I actually felt like the car was a little more stable, but more mid corner out. It still seemed to turn in. Oddly enough, I also tried some heavy rate springs with the shock in a more angled setting, which I usually run. The heavy springs also seemed to stabilize the car in certain corners, especially the sweeper. Returning to the usual Short Black spring set brought the steering back. I wonder if the stiff shock inhibits the cars ability to roll or at least, articulate the links? Chassis roll seems to be the key to cornering with the link cars.... At this point, I am running the shock with quite a bit of angle. That seems to be the best for my track conditions.

I should also add that I was encouraged to run my battery to the rear of the chassis. I had been running the short pack with the electronics behind it, but I moved the RX and ESC to the sides of the chassis and began to experiment with the battery. Full back seemed to cause to push in the sweeper, so I moved it forward a small amount at a time. What seemed to work for me was about 3/16 to 1/4" (4-6mm) off the back of the chassis. I'm finding it's easy to tune the car a little by moving the battery in small amounts.

So here is the setup sheet....for lower bite try gold side springs and a yellow center shock spring....

Thanks to The Passehls, T Marshall, RedBullFxx and Rocket Ron for the help.....

Anyway, I have been trying a of of things to get my car working consistently from session to session. I had some times where the car would be very fast, but then be no where near as good if conditions like temperature changed or traction went up or down due to car count. I also have been getting a lot of good suggestions and tips from friends and acquaintances. The big thing was to try to boil all this stuff down into something workable.

The big problem with this car being new, and a little unfamiliar, was that I did not have my "go to" adjustments figured out. Usually I have a few things that are sort of the big adjustments that will send your car in one direction or another and you know you've changed something. I had a bit of time where I felt like everything was vague and I was flailing a bit. I was trying to use both what I knew and the concepts I was learning from other people as well, and it was not meshing. So last weekend I decided to go back to the baseline to try to get my car working.

One thing I was pleased with was using a stiffer side spring. In the past I had run my Exotek car fairly stiff since it seemed to me the heavier rubber tires needed a stiffer car. I had recently began to try to make lighter springs work based on what I had seen with some of the on line setup sheets, and when the track was lower traction, it worked well. As soon as traction came up, it was not easy to drive, and in fact, somewhat unstable. It was still fast at times.

The problem with stiffer springs is that they can stabilize the car too much. The link car needs to roll a little to get around the corner, but there has to be a balance to be able to drive the car in a straight line. This is where the preload comes in. With the soft springs like Associated black or Tamiya pink/copper. you have to preload the spring a bit in a lot of cases to stabilize the car. With the softer springs, they really need to be set at just touching or even backed off the pod plate. This will dictate a lot on how the wraps the corner. With a really stiff spring, you can be backed of the pod plate so the car will rotate, but when the spring goes into compression, it will keep the car fairly flat. I think that a lot of the traction roll problems with these cars are generated from the rear of the car versus the front. This brings me to my next point, dampening.

I'm probably going to sound like a kook here, but I think that really heavy dampening is key. I had been up to 50,000 wt diff oil in the X1 damper tube, but I was wondering if maybe more could be better. After talking it over with one of my buddies who was endorsing massive amounts of dampening, I decided to go big. After some playing around, I settled on 120,000 wt Losi diff oil in the tube. This made the car much flatter, so much so that it would slide rather than traction roll. This again goes toward the theory that the much higher unsprung weight of the rubber tires requires the car to be a lot stiffer to control all that mass.

What really got the car working correctly with the higher dampening was a boatload of rear droop. I am now at 3mm over ride height. The droop seems to really give the car a lot of forward bite. I can get on the car pretty much where ever I want to. Previously, I was having to be a lot more careful with throttle inputs. Don't get me wrong, I find that smooth throttle input makes for very fast laps with F1 cars, but I feel a ton of confidence with the added bite.

At the same time, a minimal amount of front droop appears to better for me. I think it helps to keep the weight on the front tires under power to retain the on power steering. Steering feel is also less "floaty" and more direct. I had tried a lot of front droop, but I started migrating back to a minimal front droop setup, and I prefer it.

Another thing I had tried was a very horizontal shock. Usually this does produce a lot of on power steering at the expense of rear stability in my experience, but I'm not 100% sure about that now. I actually felt like the car was a little more stable, but more mid corner out. It still seemed to turn in. Oddly enough, I also tried some heavy rate springs with the shock in a more angled setting, which I usually run. The heavy springs also seemed to stabilize the car in certain corners, especially the sweeper. Returning to the usual Short Black spring set brought the steering back. I wonder if the stiff shock inhibits the cars ability to roll or at least, articulate the links? Chassis roll seems to be the key to cornering with the link cars.... At this point, I am running the shock with quite a bit of angle. That seems to be the best for my track conditions.

I should also add that I was encouraged to run my battery to the rear of the chassis. I had been running the short pack with the electronics behind it, but I moved the RX and ESC to the sides of the chassis and began to experiment with the battery. Full back seemed to cause to push in the sweeper, so I moved it forward a small amount at a time. What seemed to work for me was about 3/16 to 1/4" (4-6mm) off the back of the chassis. I'm finding it's easy to tune the car a little by moving the battery in small amounts.

So here is the setup sheet....for lower bite try gold side springs and a yellow center shock spring....

Thanks to The Passehls, T Marshall, RedBullFxx and Rocket Ron for the help.....

Wednesday, October 24, 2012

Latest V2 setup

Latest V2 setup...a little tough to drive but very fast. Need to work on on power/corner exit stability...

https://docs.google.com/open?id=0B4jXTVVFFpAoVVFmQnZrSUxfdWs

Wednesday, October 17, 2012

A caster diaster?

Another of my rambling from my visit to the track yesterday comes from the Exotek adjustable front end. I finally put my Exotek 104 with this front end on the track after working on the F104V2 for quite a while. I have run a front end made of Xpress parts which is functionally similar to the Exotek pieces, but no where near as nice or durable. So I was familiar with what usually works, but I had some ideas on things to try. Lately, with the Pit Shimizu 0571/0571/Tamiya TCS tires, the cars generally will get a little light on the inside rear coming off the corner. This will sound like diff slippage, but if you watch the cars, you cane see they are a bit rolled over. I have also talked with guys who have had this problem completely independent of us and came to the same conclusion, so that is my theory...LOL. I tend to think it is the fact that the tires are heavier, and have very good grip.

I thought that reducing caster would help this problem, as caster tends to cross jack the weight to the opposite side rear tire. I figured the outside rear was just getting way heavy from too much caster. So I set the front end to 3 degrees of caster, as I had been running 4-5 degrees. Three was actually a very good setting for taking a shot in the dark, as the car stayed pretty flat. There was still diffing, but it seemed to be reduced. Now figuring there was more of a good thing to be had I continued to try to reduce caster, but it seemed as I worked my way to 2 degrees, problems popped up. First off, the car did not like to go through the sweeper anymore. It would turn in and then push to the wall. Secondly, it didn't want to launch coming off the corner either. The mid corner push could possibly be solved with more camber or camber gain, but I didn't like the corner exit issues. Again, maybe softening the car down the middle (center shock spring/oil) could help, but the caster is a 2 for one deal on both of those issues. It may be worth investigating if the diff issue is solved, but I am also not 100% convinced a little diffing is so bad. The main problem is when the car starts to get sideways as you pull throttle, usually as the car is still loaded up from the corner. If you let the car settle before you get on it, it's not a huge problem, but to really be on it is not easy.

Going the opposite direction will generally get you going toward a traction roll. Anything much more than 5* caster on carpet is usually asking for trouble. I'm thinking 3-4* is probably the sweet spot for carpet and rubber tire.

That being said, running too much dynamic caster effect in the upper arm is probably also a contributing factor. This is spacing up the rear ball stud on the upper arm so that the caster is reduced on the loaded side - the kingpin stands up as the suspension is loaded. So now you have the loaded side reducing caster - or reducing the weight jack to the inside tire - and the unloaded side has more caster, jacking weight to the outside rear. Diff spin at it's finest!

I noticed that my F104V2 got better as I reduced the dynamic caster as the grip came up. On the fixed arms of the stock V2, this will also reduce static caster as well. I didn't reduce dynamic caster on the Exotek car, but I think this would have been helpful as well. As traction increases, you generally need less of this inclination of the upper arm. Higher grip usually means the front end is not going to wash out mid corner, and it will help reduce tendencies to traction roll as well. For a situation like asphalt, I would probably run about as much dynamic caster as I could get away with. Carpet, not so much on rubber. Foam, oh yes, but for rubber tire too much will be problematic.

I thought that reducing caster would help this problem, as caster tends to cross jack the weight to the opposite side rear tire. I figured the outside rear was just getting way heavy from too much caster. So I set the front end to 3 degrees of caster, as I had been running 4-5 degrees. Three was actually a very good setting for taking a shot in the dark, as the car stayed pretty flat. There was still diffing, but it seemed to be reduced. Now figuring there was more of a good thing to be had I continued to try to reduce caster, but it seemed as I worked my way to 2 degrees, problems popped up. First off, the car did not like to go through the sweeper anymore. It would turn in and then push to the wall. Secondly, it didn't want to launch coming off the corner either. The mid corner push could possibly be solved with more camber or camber gain, but I didn't like the corner exit issues. Again, maybe softening the car down the middle (center shock spring/oil) could help, but the caster is a 2 for one deal on both of those issues. It may be worth investigating if the diff issue is solved, but I am also not 100% convinced a little diffing is so bad. The main problem is when the car starts to get sideways as you pull throttle, usually as the car is still loaded up from the corner. If you let the car settle before you get on it, it's not a huge problem, but to really be on it is not easy.

Going the opposite direction will generally get you going toward a traction roll. Anything much more than 5* caster on carpet is usually asking for trouble. I'm thinking 3-4* is probably the sweet spot for carpet and rubber tire.

That being said, running too much dynamic caster effect in the upper arm is probably also a contributing factor. This is spacing up the rear ball stud on the upper arm so that the caster is reduced on the loaded side - the kingpin stands up as the suspension is loaded. So now you have the loaded side reducing caster - or reducing the weight jack to the inside tire - and the unloaded side has more caster, jacking weight to the outside rear. Diff spin at it's finest!

I noticed that my F104V2 got better as I reduced the dynamic caster as the grip came up. On the fixed arms of the stock V2, this will also reduce static caster as well. I didn't reduce dynamic caster on the Exotek car, but I think this would have been helpful as well. As traction increases, you generally need less of this inclination of the upper arm. Higher grip usually means the front end is not going to wash out mid corner, and it will help reduce tendencies to traction roll as well. For a situation like asphalt, I would probably run about as much dynamic caster as I could get away with. Carpet, not so much on rubber. Foam, oh yes, but for rubber tire too much will be problematic.

Front droop thoughts

I was at the track yesterday, and I had a chance to fool around with my Exotek 104 car. I was trying a lot of front end changes, and one thing that I was noticing was that personally, when I got much past .5 mm front droop, the car got a feeling mid corner that to me was not very precise on a high bite surface. I think it gives the car too much roll, but this may be useful on lower bite or asphalt. The other thing was it felt like it was over rotating. This was as i was approaching 1mm or more of front end droop over the ride height, so a ride height gauge would show 4mm at ride height, and 5mm when the suspension was extended. Once I returned to .5mm I liked the car better.

Monday, October 15, 2012

A shocking reversal........

I have been in contact with a few friends from the West Coast who told me that some of the guys were running a sedan shock on their F104V2 cars with a long shock end and the shock mount set up for the small shock that comes with the car. At first, I had it set up the wrong way, which requires you to space the mount up to clear the upper deck/brace. Here is what the correct way looks like:

I tried it on the track back to back with the "normal" sedan shock set up. It seems to make the car steer more "directly". I'll have to play around with it a little, but if nothing else it did not hurt the setup, lap times were pretty much the same.

A great way to use droop screws or how I realized how dumb I really am

So here is a quick tip on using your droop screws on the front end of your F104 based car. Normally, you are shown a button head screw with a number of washers under to set droop. This is fine and works great, but changing the setting is tedious in that you must remove some parts to access the screws easily. I had been using a button head and had drilled a hole in the top arm so I could quickly adjust up or down. This worked well, but now you are drilling the top arm. Not really the way to go an a Exotek setup.....

So it came to me, that I should use a long grub screw driven in from under the arm. This would be obvious if I was a deep thinker, which I guess I am not, LOL. It's plain as day, but I have been doing it the goofy way for months....

Anyway, this is what it looks like:

Sunday, October 7, 2012

Friday, September 28, 2012

RCFIA is awesome

A very well done web site for the RCFIA F1 series in Northern California....

I love the interviews and news bits!

http://www.rcfia.com/

Monday, September 17, 2012

F104V2 carpet setups

I have a couple carpet setups here for the V2...

These are sort of preliminary. I'm still trying to work everything out, but check it out. I think the second one is a little easier to drive.

Carpet setup #1

Carpet setup #2....note dope 1/2 fronts, full rear...

Wednesday, September 12, 2012

A quick post on ackerman for carpet on the F104V2

I was having a bit of a problem with my V2 car. Despite trying to tune around it, the car seemed to push on corner entry, but was a little loose on mid corner to corner exit, and you really had to watch how you got on the throttle. The car was not bad, just not to my exact liking. Despite fiddling around with a few different things, it didn't get a whole lot better. Finally, I decided to change the ball stud position on the steering knuckle, which is usually a pretty big change. The standard setup has the ball stud in the middle hole on the aluminum knuckle (I did get this, even though I wasn't sure if it was necessary) . I went to the most rearward hole on the knuckle, which adds a good amount of angle to the steering rods. So what this did was to make the car turn in much more positively, but also calmed it down on exit and mid corner. This was very good on the tight parts of the track. It also made it easy to drive hard off the corner, and into the sweeper. Before I had the feeling the car was going to do something weird going into the sweeper, especially if i fed it too much wheel. If I hit the line right, it went in good, but if I didn't it pushed off a little toward the wall. It was hard to know how much to turn the wheel . Anyway, now it took more throw to turn the wheels as much, but it felt like I had more "resolution" in the steering. The car could be turned into the sweeper and it held the line-I also felt I could make mid corner adjustments without upsetting the car.

So for carpet, I would recommend the rear hole. For asphalt, the middle hole might be more feasible, since you don't want the car to be as reactive turning in. That being said, as I write this, I am thinking back to running the car at Leisure Hours for the first time, and it did a lot of the things I did not like above. What might work would be the middle hole, but repositioning the servo to add some angle into the steering rods- Sort of a half measure. Obviously, the number one thing will be what you like. I think a lot of this will depend on the feel the driver prefers.

Tuesday, August 28, 2012

F104V2 carpet days.........

I had a chance to get up to the carpet track for the first time in a while. Lately, I had been racing sedans in preparation for the ROAR nationals at my local asphalt track, so F1 has been a bit on the back burner.

I wanted to try the V2 car on carpet with the Pit 0571/0572 combination. The first run was too soft on the roll springs and too stiff on the center (pitch) shock and spring. The car also didn't get onto the front end too much getting into the corner.

I went from 50wt Losi/2 hole pistons on the large sedan shock, to 50 wt Losi/3 hole pistons, and from a blue spring to a yellow spring, both from the short black spring set (standard with the F104X1). Shock length was also increased to 59mm from just under 58mm.

Now the car was able to keep up with the contours of the track a bit better. The bigger problem was the fact that the car was too soft side to side and was a bit wander-y getting onto the straight. I went from the pink spring to the silver spring and that was about perfect to keep the car a little more stable. The car also felt a little sharper on center.

I also went to 58.5mm from 59mm on the shock length a little later.

I put about 4.5mm inside the shock and just let the shock end out to get the longer lengths. 4.5mm inside will get you just under 58mm total length with the shock end run all the way up. Having tried a couple different lengths, it seems that just like the sedans, more droop gets the car on the nose more off power, but it can also give a weird floaty feeling under transition if you have too much droop. I think the shock length will be an adjustment to quickly dial in the steering feel.

The front I ran with around 1mm droop. I left this alone all day as the car was pretty good on power. I want to try a little less front droop to see if I can get a little more on power steering without throwing the setup off too much.

On the whole, I was super pleased with how easy it is to quickly tune the car with simple adjustments. The older car had limitations not only because of the t bar design, but that there was no real tweak adjustment either. Setting tweak on this car is pretty easy, and gives more control than having to replace a t bar if you feel inconsistencies in handling. There were not really any breakage issues either. I have read some reports that the links are fragile and pop off, but I have not had this problem. I also had some pretty good crashes as well, but everything is holding up. One thing I will advise is a small amount of threadlock on the screws and balls of the links. I had them start to loosen up a bit over the course of the day, so keep an eye on this.

Saturday, July 28, 2012

Saturday, July 21, 2012

Another sweet F1 video from Speedtech RC

i stumbled across another good video from the Speedtech boys at a recent UF1 race. They have some nice interviews and lots of video of new conversions and parts....

Sunday, July 15, 2012

New Tamiya F1 tires

Tamiya USA has announced a new F1 tire that fits the foam tire rim for the F104 series cars.

Tamiya USA:

"New Tamiya F1 tires for the F-104 chassis!

We are proud to announce the introduction of two new rubber tire compounds for the vastly popular Tamiya F104 Formula One chassis car kits. The front tire is a soft compound designed to offer excellent steering performance and the rear tire is a hard compound, which offers high traction with excellent longevity and durability. The new tire compounds fit the following Tamiya wheel sets: items 51378 and 54400.....

...The new item numbers for the tires are: 1031 RC F1 Tire Front (Soft) and 1032 RC F1 Tire Rear (Hard) The new tires will be available through hobby shops in early August."

Full article:

http://www.tamiyausa.com/tcs/tcs.php?article-id=556

Tamiya USA:

"New Tamiya F1 tires for the F-104 chassis!

We are proud to announce the introduction of two new rubber tire compounds for the vastly popular Tamiya F104 Formula One chassis car kits. The front tire is a soft compound designed to offer excellent steering performance and the rear tire is a hard compound, which offers high traction with excellent longevity and durability. The new tire compounds fit the following Tamiya wheel sets: items 51378 and 54400.....

...The new item numbers for the tires are: 1031 RC F1 Tire Front (Soft) and 1032 RC F1 Tire Rear (Hard) The new tires will be available through hobby shops in early August."

Full article:

http://www.tamiyausa.com/tcs/tcs.php?article-id=556

Tuesday, July 10, 2012

Saturday, July 7, 2012

Beautiful belt drive FGX

This is out of control, a totally sano belt drive FGX with fully independent suspension...

From Charles Lightfoot of UF1:

" Thank you Calvin Lee for all the hard work that went into building this car...."

More pictures: http://uf1series.com/_gallery/Cars_3.html

From Charles Lightfoot of UF1:

" Thank you Calvin Lee for all the hard work that went into building this car...."

More pictures: http://uf1series.com/_gallery/Cars_3.html

Thursday, July 5, 2012

Very Nice Setting Guide by http://www.rcformula1.com.au

Have a look at this nice setting write up by http://www.rcformula1.com.au , very useful...

http://www.rcformula1.com.au/images/docs/F1_Setup_Workshop.pdf

http://www.rcformula1.com.au/images/docs/F1_Setup_Workshop.pdf

Monday, June 25, 2012

F104 VII article by Tamiya USA

Here's a write up from Tamiya USA on the new car with some very good tuning tips for the new link rear end setup....

http://www.tamiyausa.com/articles/feature.php?article-id=613

http://www.tamiyausa.com/articles/feature.php?article-id=613

Tuesday, May 29, 2012

F1 Gold pt. 3

This week's headline, courtesy Chauncey A:

"I believe Alonso could podium a '87 four door Lumina SE"

"I believe Alonso could podium a '87 four door Lumina SE"

Tuesday, May 22, 2012

Sunday, May 13, 2012

Friday, May 11, 2012

Wednesday, May 2, 2012

Exotek link front end!!

Exotek has just announced this link front end setup for the F104..no more cobbling together hard to find parts. Looks awesome as well..nicely done.

Friday, April 27, 2012

Wednesday, April 25, 2012

Tuesday, April 10, 2012

HiroFactory HRF10X

Interesting new link chassis conversion from Japan. Looks to be similar to the Exotek, with the use of the Associated side damper.

Friday, April 6, 2012

FGX Mania

I went around the pits at the Speedtech race at the Tamiya track to get some pictures. Here's some of the 3Racing FGX cars i spotted at the race...

This is Dennis Lyman's custom FGX. I had a longer video, but somehow screwed it up. If you pause the video, you can see his car, very slick and one off!!

This is the new Exotek chassis conversion for the FGX....Exotek has many projects in store!!

A Rabbit conversion with some custom front end work..

This is Dennis Lyman's custom FGX. I had a longer video, but somehow screwed it up. If you pause the video, you can see his car, very slick and one off!!

This is the new Exotek chassis conversion for the FGX....Exotek has many projects in store!!

A Rabbit conversion with some custom front end work..

Thursday, April 5, 2012

Lightfoot does it again

Wow, this is just the camera test....what will the real thing be like???

Nice work!!

Nice work!!

Friday, March 16, 2012

The Sweetness of Fail

So I had a hard time at last week's TCS race at The Track @ Harbor Hobby. It's my home track, so I thought I would do a little better than I did. Basically, I had a hard time getting my car to work in very, very high bite conditions. From what I saw, the fastest lap in actual racing was a 8.5, by Erik Whippler. His car was really good as the bite came up, as I could see it did turn a lot. What was frustrating was that I could do 8.6 seconds laps Friday in practice, but as the bite came up my car struggled. The biggest problem was keeping the car from feeling like it was stuck "in" the track, like was screwing itself into the ground. It was pushing, and I tried quite a few things, but nothing really helped a whole lot for the race weekend.

As an aside, it appears that a few things are worth mentioning as I think due to the new 21.5 BL rules, some of the conditions have changed. First would be my recommendation of the small Mini Revo style 1800 mAh packs. Monitoring how much charge we were putting back into the packs, it was anywhere from 1400-1500 mAh. Typically, I would put about 1000-1100 mAh with silver can 540 motors in similar conditions, and the car would also work better with less weight. It appears now that not only has power consumption gone up, but also higher speeds tend to favor more weight in the car. My car worked better with the heavier packs. I used a 2700 mAh ThunderPower @ 168g, and also an Orion 3200 at about 190g. I would say at this time, this is the minimum size to work with. Also, the "shorty" packs are also worth trying in terms of adjusting weight bias in the car easily. I know several of the front running cars were using these type of batteries. Typical weight is a little over 200g.

I did have my buddy Kevin running one of my cars as well. Kevin is a very good driver and tuner, and he helped me with some of the things like the battery comparison. One thing that I did find odd was that while my car made a ton of traction no matter what tires/setting I used, his car had a very easy to drive and "free", on top of the carpet feeling that I really could not duplicate. I have to measure everything on the car, but I was amazed at how far apart the cars were, despite how closely they were set up. Kevin changed very little on the car all weekend, in fact he was able to rebuild his 416 while racing!

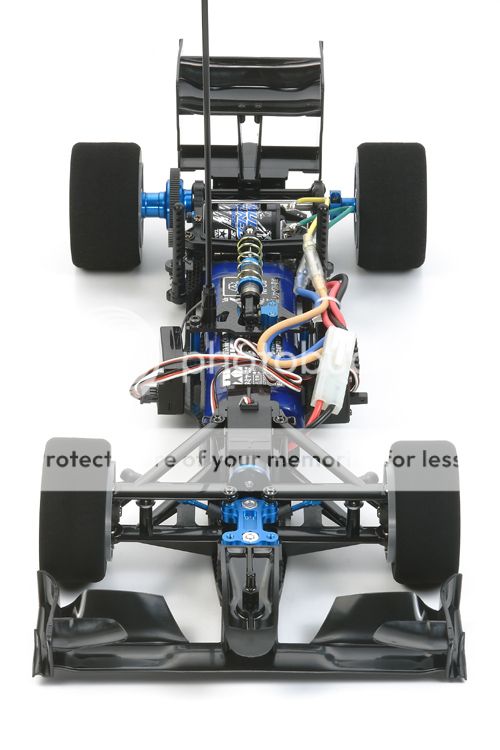

Anyway, I will have a longer rundown later. Here's Kevin's car...

As an aside, it appears that a few things are worth mentioning as I think due to the new 21.5 BL rules, some of the conditions have changed. First would be my recommendation of the small Mini Revo style 1800 mAh packs. Monitoring how much charge we were putting back into the packs, it was anywhere from 1400-1500 mAh. Typically, I would put about 1000-1100 mAh with silver can 540 motors in similar conditions, and the car would also work better with less weight. It appears now that not only has power consumption gone up, but also higher speeds tend to favor more weight in the car. My car worked better with the heavier packs. I used a 2700 mAh ThunderPower @ 168g, and also an Orion 3200 at about 190g. I would say at this time, this is the minimum size to work with. Also, the "shorty" packs are also worth trying in terms of adjusting weight bias in the car easily. I know several of the front running cars were using these type of batteries. Typical weight is a little over 200g.

I did have my buddy Kevin running one of my cars as well. Kevin is a very good driver and tuner, and he helped me with some of the things like the battery comparison. One thing that I did find odd was that while my car made a ton of traction no matter what tires/setting I used, his car had a very easy to drive and "free", on top of the carpet feeling that I really could not duplicate. I have to measure everything on the car, but I was amazed at how far apart the cars were, despite how closely they were set up. Kevin changed very little on the car all weekend, in fact he was able to rebuild his 416 while racing!

Anyway, I will have a longer rundown later. Here's Kevin's car...

Sunday, March 11, 2012

Wednesday, February 22, 2012

Tuesday night F1

I just wanted to do a quick post on foam tires to follow up on my Omaha TCS report. I got back to the track today and I had a chance to run my F104 pro from the race and my F104X1. After having good success with the Pro car, I thought the X1 would actually be pretty good as well due to similar chassis setup.

The Pro with the short upper deck and FRP lower was actually .3 second per lap faster with no problem. The X1 still had some elements of an outdoor rubber tire setup on it. I had the heavy pivot post still installed, and it made my car kind of herky jerky. The car did not flow in and out of the corners. Going to a normal aluminum piece smoothed the car right out, but now it had a strange feeling like something was not right with the rear end of the car. I felt like it turned a little better one way than the other. I then decided to take the counterweight off the axle and run a normal clamp hub. Again, the car got better. I'm not sure if the counter weight is better for rubber tire, but I didn't like it for foam.

I tried the damper tube with 2000 wt oil, which I had from outdoor racing. This was not enough dampening for my taste on carpet with foam. I went to 10K but it felt a little light on the bench, and again, the car was rolling too much. 30K turned out to be very good. At first, I thought it felt thick, but it was very nice on the track.

I ran the 2 forward posts on the upper deck, and that worked pretty well, but there were time when the car didn't want to turn in for me. When i had made all these changes, the car was able turn the same lap time as my Pro, and maybe even be a bit more planted.

I have a long upper deck for the X1 in my possession, and i think that may be the key to get that little bit of turn in I'm looking for. I think only using the 4 screws to hold the upper deck to the servo mount and the pivot post should allow plenty of twisting effect but the front to rear stiffness should help the turn in. We shall see. Stay tuned....

The Pro with the short upper deck and FRP lower was actually .3 second per lap faster with no problem. The X1 still had some elements of an outdoor rubber tire setup on it. I had the heavy pivot post still installed, and it made my car kind of herky jerky. The car did not flow in and out of the corners. Going to a normal aluminum piece smoothed the car right out, but now it had a strange feeling like something was not right with the rear end of the car. I felt like it turned a little better one way than the other. I then decided to take the counterweight off the axle and run a normal clamp hub. Again, the car got better. I'm not sure if the counter weight is better for rubber tire, but I didn't like it for foam.

I tried the damper tube with 2000 wt oil, which I had from outdoor racing. This was not enough dampening for my taste on carpet with foam. I went to 10K but it felt a little light on the bench, and again, the car was rolling too much. 30K turned out to be very good. At first, I thought it felt thick, but it was very nice on the track.

I ran the 2 forward posts on the upper deck, and that worked pretty well, but there were time when the car didn't want to turn in for me. When i had made all these changes, the car was able turn the same lap time as my Pro, and maybe even be a bit more planted.

I have a long upper deck for the X1 in my possession, and i think that may be the key to get that little bit of turn in I'm looking for. I think only using the 4 screws to hold the upper deck to the servo mount and the pivot post should allow plenty of twisting effect but the front to rear stiffness should help the turn in. We shall see. Stay tuned....

Thursday, February 16, 2012

Wednesday, February 15, 2012

TCS Omaha 2012

Ahh well once again the TCS series begins for me, this time in Omaha, Nebraska. The HobbyPlex/Hobbytown is an excellent facility, and I have been there quite a few times. That fact also makes me a big dummy.

You see I showed up Saturday morning. I didn't think about it, but there was Friday practice, which I should have attended. The HobbyPlex's carpet is a little different than most other carpet tracks in that it rarely becomes super high traction. In the past, I have done some things not common for carpet racing. In the F103 days, I showed up at a TCS race there with a 15th anniversary car, all graphite parts, ready for some carpet racing. Well, the car was only "ok". My ever astute buddy Kevin Kane noticed one of the cars was getting around pretty good. He then asked what version of car it was out on the track. I said I thought the guy has a regular F103RM with the fiberglass chassis. "Bingo...do you have a fiberglass chassis?" 20 minutes later, I was on the track, laughing out loud about how much better the car was with the flexier fiberglass chassis. I went from ok to dialed just by going to the softer chassis.

So like a big dummy I show up with a F104 with a graphite plate and full long upper deck. The car was "ok" but it would actually 4 wheel drift on some parts of the track. Not good.

I had the A kit tires all the way around, like my Harbor hobbies setup from 2011. The car was just not very good, even after changing some of the front end setting to get more steering. Now it had some steering, but would break the rear loose a bit. I wound up a lap off the pace of Erik Whippler in the first qualifier.

Jay Streeter, long time TCS regular was sitting next to me with a split upper deck on his F104. I was reluctant to try it, but after fooling around all morning with little results, I decided to put it on. The problem now was that the car had crazy amounts of steering. I went out with A tires front and rear and the car was undriveable. So basically i threw a qualifier away, but the good thing was I had earlier tried B tires all around, and the car lost steering with the older long top deck. Jay had also been running B fronts and A rears, which he said worked great. So I went to the A rear-B front combination, and also a fiberglass lower chassis, in addition to the split top deck for max traction. The upper deck was mounted with o rings under the screws to add even a bit more flex.

I ran the car around during the break between heats, and it was pretty good. Unfortunately, i would up having a problem with the lead to my transponder. It had become stressed and frayed, allowing the lead to short itself, and kill the receiver power. Of course, it didn't cause problems until about 10 seconds before I went out for the 3rd qualifier. The car kept shutting off, and I didn't know why. It took about 30 minutes in the pits to figure out what was going on...ugh. The only good thing was that there was practice after the heats were over.

I stayed and ran packs trying to get the car dialed in. I also went to the soft tbar without the cutout. Jay had been running this too ( I was stealing a lot of ideas from Jay). Now the car was really good, and I could equal the fast lap of the day.

For the final qualifier on Sunday morning, I just wanted to run a decent race and try to move up from 4th or 5th or where ever I was. I went out with the tires doped a little more than 1/2 on the front. The track had picked up some traction from when I ran the car in practice Sunday morning, as I found out. For the first minute or two, the car was hard to drive. I was running good laps, but not fast enough to challenge for TQ. As the car settled in, I was able to be more aggressive, and run tighter and faster. I wound up finishing less than 2 seconds off of TQ, which was Whippler. Had the car driven better at the start of the race, I think I may have been able to be even closer, or even TQ. Close doesn't count for much.

Anyhow, I started second for the mains. When the first main went off, my car was very good, and came off the starting line great. Erik seemed like he was trying to stay conservative, and I tried to challenge him before he could get away. We stayed close, and I tried to pass as he was a little wide on some corners, but i could never get in far enough before he shut the door on me. I didn't want to cause contact, so I hoped to wait until he made a big enough mistake to get by. Unfortunately, I wound up making the mistake and fell back after around 1:30 or 2 minutes. I tried to catch up, but I made a couple more mistakes trying to run as tight as possible. I still finished 2nd, so I was in decent shape.

On the start of the second main, I felt my car was even better after some hot laps. This is where I went wrong. On the tone, I ripped the throttle, and got a good start, and it appeared that Erik's car may not have started as well as mine had. I gained a couple feet, but the first turn was a 180 into an S section. From my recollection (which is never too good when you're racing) I think Erik went a little wide, and I tried to go under. The problem was I realized Erik was now going to be turning into me and I tried to stay to the inside, but i dotted the board and went out to the outer wall. The whole field went by..race over... I was able to get back up to third, but Erik now had 2 wins, so the race was over. Tim Ski who had finished 3rd the first race got 2nd, so I would have to win the third race to get second. I drove just as badly the third main, dotting out on the first lap. Tim finished 2nd overall, and I got 3rd.

I drove badly in the mains for sure. The first race wasn't too bad, but I should have taken it easy after I made a mistake, since I didn't fall too far back. Trying to push too hard just lead to more mistakes. In the second main, I should have just backed down a bit after I saw I was catching the TQ car. The first series of corners was too dangerous to try any sort of maneuvers to pass or challenge. Had I waited until we came to a better section of the track, or even after the first lap, I may have had a chance. I think my car was as good as any of the others, I just was driving with my head up my butt.

Lessons learned: Get to the track for practice, and remain calm on the driver's stand!!

You see I showed up Saturday morning. I didn't think about it, but there was Friday practice, which I should have attended. The HobbyPlex's carpet is a little different than most other carpet tracks in that it rarely becomes super high traction. In the past, I have done some things not common for carpet racing. In the F103 days, I showed up at a TCS race there with a 15th anniversary car, all graphite parts, ready for some carpet racing. Well, the car was only "ok". My ever astute buddy Kevin Kane noticed one of the cars was getting around pretty good. He then asked what version of car it was out on the track. I said I thought the guy has a regular F103RM with the fiberglass chassis. "Bingo...do you have a fiberglass chassis?" 20 minutes later, I was on the track, laughing out loud about how much better the car was with the flexier fiberglass chassis. I went from ok to dialed just by going to the softer chassis.

So like a big dummy I show up with a F104 with a graphite plate and full long upper deck. The car was "ok" but it would actually 4 wheel drift on some parts of the track. Not good.

I had the A kit tires all the way around, like my Harbor hobbies setup from 2011. The car was just not very good, even after changing some of the front end setting to get more steering. Now it had some steering, but would break the rear loose a bit. I wound up a lap off the pace of Erik Whippler in the first qualifier.

Jay Streeter, long time TCS regular was sitting next to me with a split upper deck on his F104. I was reluctant to try it, but after fooling around all morning with little results, I decided to put it on. The problem now was that the car had crazy amounts of steering. I went out with A tires front and rear and the car was undriveable. So basically i threw a qualifier away, but the good thing was I had earlier tried B tires all around, and the car lost steering with the older long top deck. Jay had also been running B fronts and A rears, which he said worked great. So I went to the A rear-B front combination, and also a fiberglass lower chassis, in addition to the split top deck for max traction. The upper deck was mounted with o rings under the screws to add even a bit more flex.

I ran the car around during the break between heats, and it was pretty good. Unfortunately, i would up having a problem with the lead to my transponder. It had become stressed and frayed, allowing the lead to short itself, and kill the receiver power. Of course, it didn't cause problems until about 10 seconds before I went out for the 3rd qualifier. The car kept shutting off, and I didn't know why. It took about 30 minutes in the pits to figure out what was going on...ugh. The only good thing was that there was practice after the heats were over.

I stayed and ran packs trying to get the car dialed in. I also went to the soft tbar without the cutout. Jay had been running this too ( I was stealing a lot of ideas from Jay). Now the car was really good, and I could equal the fast lap of the day.

For the final qualifier on Sunday morning, I just wanted to run a decent race and try to move up from 4th or 5th or where ever I was. I went out with the tires doped a little more than 1/2 on the front. The track had picked up some traction from when I ran the car in practice Sunday morning, as I found out. For the first minute or two, the car was hard to drive. I was running good laps, but not fast enough to challenge for TQ. As the car settled in, I was able to be more aggressive, and run tighter and faster. I wound up finishing less than 2 seconds off of TQ, which was Whippler. Had the car driven better at the start of the race, I think I may have been able to be even closer, or even TQ. Close doesn't count for much.

Anyhow, I started second for the mains. When the first main went off, my car was very good, and came off the starting line great. Erik seemed like he was trying to stay conservative, and I tried to challenge him before he could get away. We stayed close, and I tried to pass as he was a little wide on some corners, but i could never get in far enough before he shut the door on me. I didn't want to cause contact, so I hoped to wait until he made a big enough mistake to get by. Unfortunately, I wound up making the mistake and fell back after around 1:30 or 2 minutes. I tried to catch up, but I made a couple more mistakes trying to run as tight as possible. I still finished 2nd, so I was in decent shape.

On the start of the second main, I felt my car was even better after some hot laps. This is where I went wrong. On the tone, I ripped the throttle, and got a good start, and it appeared that Erik's car may not have started as well as mine had. I gained a couple feet, but the first turn was a 180 into an S section. From my recollection (which is never too good when you're racing) I think Erik went a little wide, and I tried to go under. The problem was I realized Erik was now going to be turning into me and I tried to stay to the inside, but i dotted the board and went out to the outer wall. The whole field went by..race over... I was able to get back up to third, but Erik now had 2 wins, so the race was over. Tim Ski who had finished 3rd the first race got 2nd, so I would have to win the third race to get second. I drove just as badly the third main, dotting out on the first lap. Tim finished 2nd overall, and I got 3rd.

I drove badly in the mains for sure. The first race wasn't too bad, but I should have taken it easy after I made a mistake, since I didn't fall too far back. Trying to push too hard just lead to more mistakes. In the second main, I should have just backed down a bit after I saw I was catching the TQ car. The first series of corners was too dangerous to try any sort of maneuvers to pass or challenge. Had I waited until we came to a better section of the track, or even after the first lap, I may have had a chance. I think my car was as good as any of the others, I just was driving with my head up my butt.

Lessons learned: Get to the track for practice, and remain calm on the driver's stand!!

Friday, February 10, 2012

F104 front end...once again

I was fooling around with some things at the track, and one was using the Tamiya short ball stud on the rear of the upper arm. Most of the time I run the standard size ball stud, or even use shims under the ball stud to raise the height. The short ball stud looks to be 1mm shorter than standard.

I was using my Harbor Hobbies TCS foam setup from last year to prepare for the upcoming TCS races. Shortening the rear upper ball stud took caster out from this setup, which made the car want to slide instead of traction roll...exactly the same thing it does with rubber tires. Just shortening this mounting point may not have 100% the same results for everybody, since there are some specific things I'm doing with the kingpin spacing as well that probably affect caster angle. At the same time, getting a little caster out of the car can help if you pick up a traction roll.

I was using my Harbor Hobbies TCS foam setup from last year to prepare for the upcoming TCS races. Shortening the rear upper ball stud took caster out from this setup, which made the car want to slide instead of traction roll...exactly the same thing it does with rubber tires. Just shortening this mounting point may not have 100% the same results for everybody, since there are some specific things I'm doing with the kingpin spacing as well that probably affect caster angle. At the same time, getting a little caster out of the car can help if you pick up a traction roll.

Thursday, February 2, 2012

Serpent new F1

Stolen from rcbonus... front end looks good, it even appears the rear tires are possibly a hex like Tamiya...

However, it's hard to say how wide it is. Looks to me like 200mm, and that body looks like a 3 racing F109 kit shell...

However, it's hard to say how wide it is. Looks to me like 200mm, and that body looks like a 3 racing F109 kit shell...

Wednesday, February 1, 2012

F201 tires fit Ride F104 rims

I mentioned this on RCTech, but Tamiya F201 tires fit Ride F104 wheels perfectly. So if you have any of these tires NOS or you hobby store does, you can put them to good use. The F201 tires actually worked pretty well...

Sorry it's a phone photo..a little blurry

These guys http://www.harbor-hobby.net/ have a bunch of sets of A's and B's...Ask for Eric, he can set you up with tires..

Sorry it's a phone photo..a little blurry

These guys http://www.harbor-hobby.net/ have a bunch of sets of A's and B's...Ask for Eric, he can set you up with tires..

Wednesday, January 4, 2012

Traction rolling and you...

I have not only had quite a bit of traction rolling myself as I have been learning rubber tires on my F104 cars, but I have also been in contact with guys who have been traction rolling as well. Much of this stems from the narrow width of the cars. There have been many different cures- heavier side spring, lighter side spring, no side spring, (in the case of the link cars), less camber, less caster, different Tbar, and so on.

So anyway, I was at the track tonight, and the bite came up at the end of the night. My #1 thing to start with is glueing the sidewalls of the tires, tires are 80-90% of the handling, right?

This is my tire after I re glued the sidewall. I had glued it previously, but that was a few weeks and many, many runs ago. As the bite came up, my car started lifting wheels and flipping. At first, I tried to reduce camber, take a bit of caster out, thinking it was a small problem. Really, the glue had been wearing off from all the runs I had made. Now, after re-gluing the tires, the traction roll went away and the car actually could push and/or slide, instead of flipping.

More sucky pictures..any who, because I was fooling with the suspension instead of gluing the tires up, I got my setup away from what was working before. With the reduced sidewall grip, I could now add back that camber and caster without the car doing triple axles in the sweeper.

The rear tire can almost be as important as the front. If the car drifts sideways at all, that rear can grab as well and put the car over.

So in closing, when you are getting too much lateral grip, remember, start with a nice fat bead of CA glue on the sidewall, right up to the carcass of the tire. Keep an eye on it's condition, too. It will start to wear after a decent amount of runs.

So anyway, I was at the track tonight, and the bite came up at the end of the night. My #1 thing to start with is glueing the sidewalls of the tires, tires are 80-90% of the handling, right?

This is my tire after I re glued the sidewall. I had glued it previously, but that was a few weeks and many, many runs ago. As the bite came up, my car started lifting wheels and flipping. At first, I tried to reduce camber, take a bit of caster out, thinking it was a small problem. Really, the glue had been wearing off from all the runs I had made. Now, after re-gluing the tires, the traction roll went away and the car actually could push and/or slide, instead of flipping.

More sucky pictures..any who, because I was fooling with the suspension instead of gluing the tires up, I got my setup away from what was working before. With the reduced sidewall grip, I could now add back that camber and caster without the car doing triple axles in the sweeper.

The rear tire can almost be as important as the front. If the car drifts sideways at all, that rear can grab as well and put the car over.

So in closing, when you are getting too much lateral grip, remember, start with a nice fat bead of CA glue on the sidewall, right up to the carcass of the tire. Keep an eye on it's condition, too. It will start to wear after a decent amount of runs.

Poor man's F1R part II

Sorry about the semi sucky photos, but I took them with my video camera. Anyway, this is the little plate I made for my Exotek F104 conversion. It does allow the car to be a bit more flexible. Maybe not as much as the F1r, and it probably does not have as much rear bias, but that may be ok for carpet racing anyway.

More of an overhead view here. I made it possible to use up to 4 posts for the top deck. Here i am only using the rearmost two of the four.

You can get a little better idea of the layout, there is quite a bit of open area with a short 3800 battery.

I tried the battery moved forward a bit as well, but I found it was actually very good all the way back.

Mostly I made this part because I don't have the cash flow for the F1R yet, but it does seem to make more traction...

More of an overhead view here. I made it possible to use up to 4 posts for the top deck. Here i am only using the rearmost two of the four.

You can get a little better idea of the layout, there is quite a bit of open area with a short 3800 battery.

I tried the battery moved forward a bit as well, but I found it was actually very good all the way back.

Mostly I made this part because I don't have the cash flow for the F1R yet, but it does seem to make more traction...

Subscribe to:

Comments (Atom)