The TRF101 180mm carbon front end parts are becoming somewhat popular among Tamiya TCS racers with the various F1 models due to the simplicity and less aggressive nature of it's geometry. I personally like it on the TRF102 for carpet. On pretty much any other model, for carpet racing, I prefer the standard F104 front end. My familiarity with it, and the amount of grip it produces in a higher traction setting has been an overall plus for me.

On asphalt, things are more of a toss up. Most of the Tamiya F104 models have a little mid corner/on power push when the front to rear balance is right, unless traction is very high. One of the most popular tire setups is the kit front, TCS (pit shimizu) rear combination. The reason for this is the more forgiving nature of the kit front tire vs. a very grippy TCS front.

The TRF102 changed this a bit, since the more flexible 2.5mm chassis gives the front end of the car more bite, and a lot more steering throughout the corner. This is my personal weakness, since more steering has always translated to speed for my driving style with the Tamiya cars. The problem is that this also makes the TRF102 a hard beast to tame if the rear end of the car is not locked in. Even if so, inconsistency and the dreaded traction roll can bite you...

I built and ran a TRF102 for the TCS nationals last year, which in hindsight may have not been the best decision. The car was great, and I think is an excellent design, but the amount of time between its release and the nationals was not really enough to fully dial in the car in relation to how familiar and comfortable I was with my F104WGP on asphalt. The temptation of the awesome steering feel was too much to overcome. The problem was a lack of spares in the thin T bar department, due to how new the car was, and the somewhat unpredictable nature of the car for me. Last year's champ Tyree Phillips certainly had no problem, winning with the 102, but he is also about 1500 miles closer to the Tamiya track than I am for testing sessions.

In any event, I was able to return to the Tamiya facility for the spring TCS regional race in a attempt to get some more testing there with the 102 car. While racing was not particularly successful with a 7th place finish, I got a lot of good feedback and testing in. I had decent pace very quickly, more so than any other visit to the Tamiya track. Even more important, I had a good car to bring back home and make comparisons at my home track.

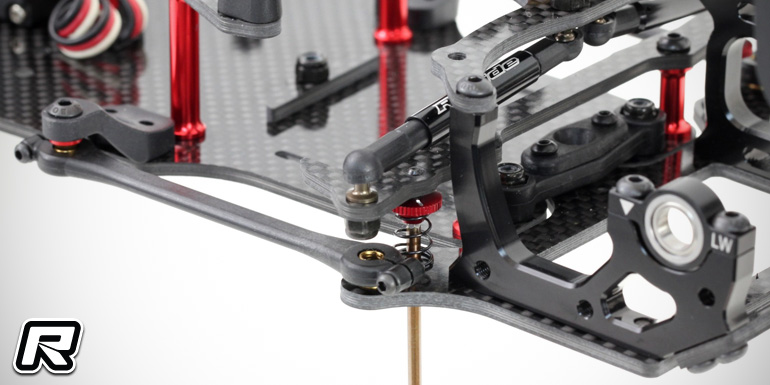

While at Tamiya, I was able to check out past TCS champion Craig 'CUDA Hammond's TRF102, which he claimed to eclipse even his venerable championship winning F104 in "monkey car" ease of driving and crazy speed. His biggest departure from the norm was the carbon front end. I had a TRF101, but I was never overly impressed with the front end. That version of the carbon front end, a bit of a half measure featuring the plastic lower arms of the F104, never gave me the steering feel I was looking for. I had talked to some racers about the carbon front end, but nobody else seemed to have many conclusions either. Craig, however, was a believer... A believer who regularly hands out beatings, so I figured it would be worth a try. I got a second car, and I also happened to win a front end setup at a carpet TCS regional, to it all came together like it was meant to be.

In the opening weeks of the outdoor season at the local track, I brought out multiple cars to compare to the track tested stock TRF102 to get a baseline on performance. The 102 tuned for the Tamiya track was certainly the best car of the lot, with the carbon front end car (CFE) close, but definitely lacking some of the steering of the standard car.

Several weeks of testing between the two TRF cars resulted in the standard car remaining top dog. I did not change the standard 102 except tire prep to have a good idea of what a car that worked at the nationals's track would perform and feel like while I worked on the CFE car.

The only thing I did not like about the CFE TRF102 was that it didn't produce the lap times of standard car. It was quite a bit easier to get the car around, and got into the corner better under the brakes. It was also really consistent over a run. The standard 102 shined best when the traction was up; it lost out if the traction was lower, becoming inconsistent.

I built the CFE car to the instructions with the spacers included resulting in a ride height close to 6 mm. That may sound a bit crazy, but I wanted to run the front end the way the instructions said at first, and a little "motor boat" reverse rake will make a stable car. Besides, Craig's car was set up like that, so it's all good! However, I decided to try a little change to see if I could get some more speed and steering. I had a gut feeling that if I could get the car to roll through the corner a little better, it would be at least as fast as the standard car, but more docile. That would be especially important in varying traction.

I dropped the car down to 4.5 mm ride height, changing the lower arm spacers to 5 mm. I didn't change anything else. That may have also been part of what would come later.

The first run with the lowered car was after racing ended, at a time when the track usually loses a little bite. My best lap during racing with the standard car was a 19.0, and after the races it would not match that lap as the track went away. The CFE car was able to hit an 18.7 right away, better than anything I did all day. Even more impressive, I assumed that car would be slow based on feel. Easy to drive, but checking the lap counter after the run, the results were there. I immediately prepared the standard car again, thinking possibly the track had gotten better somehow. It would not break the 19 second barrier that run. The second run on the CFE car I lowered the rear axle one position as well, thinking it might help add just a touch of rear bite. That change resulted in a ridiculous 18.4 hot lap, 0.6 better than the standard car's best lap. That was totally exciting, to the point of concern that somehow the speed might not translate to the Tamiya America track later in the summer. I have been bitten in the past by the differences in track characteristics, but the more docile nature of the CFE car tends to bode well from my experiences at the nationals. Usually, my problems come form a more aggressive, but faster-at-home car.

What made the car so much faster?....I'm not 100% sure. The increased steering certainly was helped by lowering the car about 1.5 mm. The other factor may have been in the bump steer and ackermann. Raising the suspension arms did also raise the steering knuckle in relation to the servo saver. This usually biases the steering more toward corner entry. A car with the links much higher at the servo saver than the knuckle will bias toward corner exit steering, so much so that extreme settings can make the car pirouette on the nose. That change must have been fairly subtle anyway, since the car drove almost the same as it did before the changes.

It is of interest to note that lowering the car brought enough steering that I was able to reduce or eliminate doping the front tire. Typically I had sauced the entire front, but now 1/4 or no dope was plenty of steering. Reducing steering should not be a problem, and adding should simply be a matter of more sauce on the front end. That's also a positive sign, as a car that is good and can be tuned with small tweaks like tire sauce application will be consistent run over run during the day. The driver will be able to concentrate on learning to drive the car at 10/10 and really find the subtleties to wring out the best lap times.

In any event, the testing will continue, but the carbon front end is winning right now.

Friday, June 3, 2016

V2 thing...V2!!

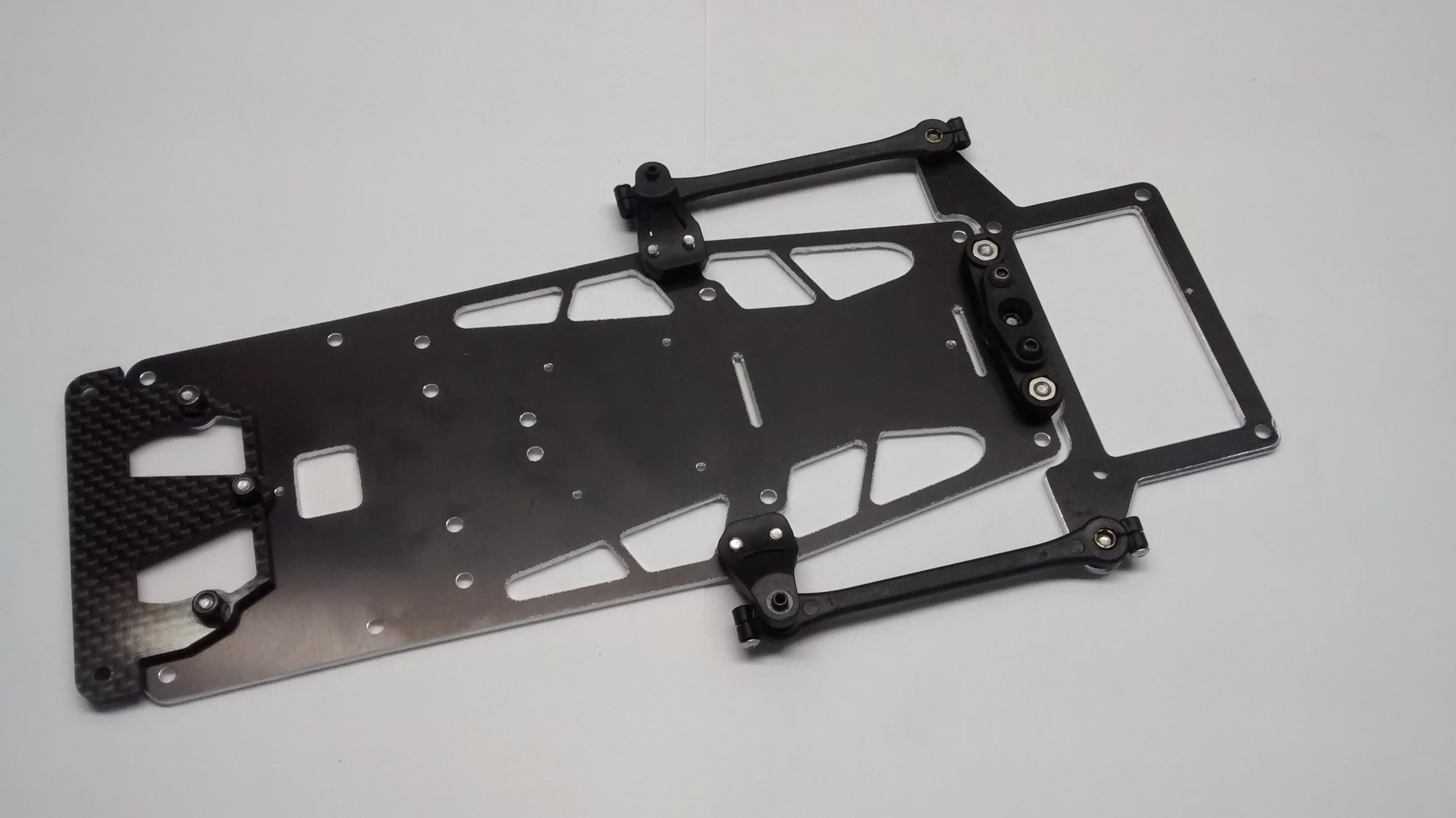

I still have the V2Thing that I wrote about some time ago. I have run it a bit, but never put a ton of time into it. It has had ups and downs in the small amount of time I have run it, but mostly it has been about trying some new ideas.

Not shown in the picture is the 3mm spacer used to bring the link back down to a level orientation with the pod end of the link

Once I get the whole car together, it should be fun to get a little track time and see what I can do with the revamped V2-V2!

Anyway, I have been thinking of a way to get a transverse pack into the car. Wider links would be needed. I did want to preserve the long, angled link premise I was working with.

Lately, a new 1/12 aluminum chassis conversion has popped up, utilizing the hanging link carriers from the Roche f1 car. The makers are claiming a great increase in corner speed due to reduced touch down/scrub in the corner.

So in that vein, I decided to make a little change in the V2 Thing that would kill two birds with one stone....

I had a scrap chassis that was perfect for making some hanging link mounts, along with some F201 shock crank posts that made nice standoffs. The F201 parts I had laying there, but Tuning Haus makes nice threaded standoffs in a variety of colors and sizes.

Now I have a super narrow chassis that will fit a transverse shorty pack, and approximately 8mm forward and aft movement for battery placement.

Not shown in the picture is the 3mm spacer used to bring the link back down to a level orientation with the pod end of the link

Once I get the whole car together, it should be fun to get a little track time and see what I can do with the revamped V2-V2!

Subscribe to:

Posts (Atom)