I got a chance to run my car on asphalt for the first time today. My initial thought was that it actually understeered a bit. This may have been due to the tire treatment. I was trying to actually use an oil type additive, but after the warmers came off, I re cleaned the tire with buggy grip. This seemed to clear up a lot of the issue with the tires feeling "greasy". The car actually was fairly locked down.

I was also using 28g of weight on and around the servo. This is an idea based on the new 1/12 layouts using the battery lengthwise in the car to get more weight in the nose area to promote more on power steering and a bit less twitchyness. It's like putting a case of water in the front of a shopping cart. It doesn't change directions so fast, but it goes once you are committed.

Anyway, I started to increase the angle of the upper arm by lowering it at the inside by 1mm, and on subsequent runs, raising it at the kingpin by .5mm. I also went to 2.0 camber. This made a lot of off power steering, but it didn't turn that hard on the throttle To help this, I went the yellow spring, from the red. Again, it was helpful, but not a huge difference. Lowering the shock ballstud by 1mm did get the car steering a little more as well.

Adding 1mm to the reactive caster (placing the shims under the rear upper arm ballstud) again got the car turning more off power, but didn't help the on power much at all.

Raising the front ride height 1mm did actually seem to help a bit. I sort of think the car could roll a bit faster with the nose up. I'm not sure about this, so I'm going to have to try it a little more. It did seem promising.

One other thing I did have a chance to try was changing the damper tube. I started with 5000 diff lube, and went down to 2000. The car had quite a bit less dampening, and it also had more response. It was a bit hard to get a really good handle on this, as I had a set of tires starting to go off when I did this, and I went to a newer set on the next run. I'm tending to think it may be better off to actually run a little stiffer lube when there is less bite to the car is calmer. Obviously, this only holds true to a point, but 5K to 10K should be ok. I would say start with 5000 and go from there.

Overall, the car was a little on the push side, but I could drive it fairly hard and not have to worry about it spinning out or acting funny otherwise. I did identify an on power push, but this car may require a harder spring and or shock oil setup, since the damper disc acted in all directions, vs. the tube which only affects side to side movement.

It was a bit hard to play around with too much more, as the race was a local series race that had around 70 entries. Track times was a bit of a premium, but I'm going to try to get more practice this week and work through some of the issues.

Sunday, July 31, 2011

Sunday, July 24, 2011

Exo104 and 104X1

The weather has been weird around here lately. Hot, crazy thunderstorms, everything changing every 15 minutes. With that being the case, it was time for a trip to the carpet track.

I wanted to shake down the 104X1, and also fool around with my Exotek car. I got a hold of some of the Pit tires last week (R-1 and F3-S), so it would be a nice time to try them out on carpet. Luckily, the layout has been down a couple months since its summer. There are at least a few guys practicing every week, so the traction was ok.

The Exotek car was pretty good to start with, but it didn't quite rotate enough, and had a bit of a mid corner push. I changed the ballstud on the rear of the upper arm from a short Tamiya to the standard Tamiya, which is about 1mm higher. That helped to get the car turning mid corner, but it picked up a traction roll if I cranked the wheel too hard in the sweeper. Reducing camber to 1.5* helped a little, but I wound up changing the 3.5 mm offset steering arms for the stock parts. This helped since I was able to take throw out of the radio, and the car transitioned side to side way better. Basically, the car had more steering with less throw, so it wasn't diving onto the outside tire so hard and traction rolling.

At this point I threw the Pit tires onto the 104X1 just to make sure it went in a straight line, steered ok, and just to see what it drove like. I was actually surprised at how good it was. It wrapped the corners a little better than the Exotek car, and had quite a bit of off power steering. At the same time, it pushed if you got on the throttle too quick, and it didn't have the overall front grip of the Exotek, nor was it as easy to drive.

I took one of the 1.5mm washers out from under the rear shock ball stud, making the shock a bit flatter. That made the car better on power, but also took away a bit of rear grip.

After all that, I looked at my Exotek car and made a few changes to get it closer to some of the things I liked on the X1. I went from 50wt in the side damper to 35wt oil, and from red CRC side springs to whites, one step down. I measured the front caster on the X1, and put the Exotek car at about 7*, or as close as I could eyeball with my camber gauge. I also lowered the front ride height 1mm.

This really helped the car wrap the corners much better. It was fast but really easy to drive. The only thing you had to be aware of was not totally sawing the wheel hard in the sweeper. Some of that may just be the nature of the beast, in that the car is so narrow. I also noticed the car was only making a few small chirps in a couple corners, so it was using the tires without sliding them. That was one thing about the X1, it was making a lot of tire noise.

Another small but significant change was the servo saver. I was using a small Kimbrough, but it had a crack on the edge of one of the ballstud holes. It broke when I got into a tube, so I replaced it with a Kimbrough Medium (they are black, and come with inserts for different servos). The ball stud holes are are further apart, and a little farther away from the center of rotation. This repair was the only change before I went back out on the track, and I noticed the car had more steering without upsetting any other part of the setup. I had tested out all 3 sizes of Kimbroughs, and the big Tamiya horn last summer with the servo positioned per the manual. I hadn't gone through that test again once I started to run the servo with the output shaft facing up. Last summer the Kimbrough Medium had the most steering, and also produced better lap times (I had a hard time believing there was a difference, but there it was). Once again, the Kimbrough Medium was an improvement.

I ran the X1 one more time, just to compare the two cars. The X1 was definitely fast, but a little more on edge. As I said above, it made a lot of tire noise, and with the shock a little more level, you could tell it was sliding a bit in the sweepers. I think some of that could be remedied by playing with the o rings on the T bar, maybe running only one o ring vs. the inner and outer o rings. The car did have a very good feel, and was shockingly close on setup. With a few changes, it will be really good. I'm going to try to get it out on asphalt ASAP with the Tamiya tires to see where it really stands, but so far, so good.

I wanted to shake down the 104X1, and also fool around with my Exotek car. I got a hold of some of the Pit tires last week (R-1 and F3-S), so it would be a nice time to try them out on carpet. Luckily, the layout has been down a couple months since its summer. There are at least a few guys practicing every week, so the traction was ok.

The Exotek car was pretty good to start with, but it didn't quite rotate enough, and had a bit of a mid corner push. I changed the ballstud on the rear of the upper arm from a short Tamiya to the standard Tamiya, which is about 1mm higher. That helped to get the car turning mid corner, but it picked up a traction roll if I cranked the wheel too hard in the sweeper. Reducing camber to 1.5* helped a little, but I wound up changing the 3.5 mm offset steering arms for the stock parts. This helped since I was able to take throw out of the radio, and the car transitioned side to side way better. Basically, the car had more steering with less throw, so it wasn't diving onto the outside tire so hard and traction rolling.

At this point I threw the Pit tires onto the 104X1 just to make sure it went in a straight line, steered ok, and just to see what it drove like. I was actually surprised at how good it was. It wrapped the corners a little better than the Exotek car, and had quite a bit of off power steering. At the same time, it pushed if you got on the throttle too quick, and it didn't have the overall front grip of the Exotek, nor was it as easy to drive.

I took one of the 1.5mm washers out from under the rear shock ball stud, making the shock a bit flatter. That made the car better on power, but also took away a bit of rear grip.

After all that, I looked at my Exotek car and made a few changes to get it closer to some of the things I liked on the X1. I went from 50wt in the side damper to 35wt oil, and from red CRC side springs to whites, one step down. I measured the front caster on the X1, and put the Exotek car at about 7*, or as close as I could eyeball with my camber gauge. I also lowered the front ride height 1mm.

This really helped the car wrap the corners much better. It was fast but really easy to drive. The only thing you had to be aware of was not totally sawing the wheel hard in the sweeper. Some of that may just be the nature of the beast, in that the car is so narrow. I also noticed the car was only making a few small chirps in a couple corners, so it was using the tires without sliding them. That was one thing about the X1, it was making a lot of tire noise.

Another small but significant change was the servo saver. I was using a small Kimbrough, but it had a crack on the edge of one of the ballstud holes. It broke when I got into a tube, so I replaced it with a Kimbrough Medium (they are black, and come with inserts for different servos). The ball stud holes are are further apart, and a little farther away from the center of rotation. This repair was the only change before I went back out on the track, and I noticed the car had more steering without upsetting any other part of the setup. I had tested out all 3 sizes of Kimbroughs, and the big Tamiya horn last summer with the servo positioned per the manual. I hadn't gone through that test again once I started to run the servo with the output shaft facing up. Last summer the Kimbrough Medium had the most steering, and also produced better lap times (I had a hard time believing there was a difference, but there it was). Once again, the Kimbrough Medium was an improvement.

I ran the X1 one more time, just to compare the two cars. The X1 was definitely fast, but a little more on edge. As I said above, it made a lot of tire noise, and with the shock a little more level, you could tell it was sliding a bit in the sweepers. I think some of that could be remedied by playing with the o rings on the T bar, maybe running only one o ring vs. the inner and outer o rings. The car did have a very good feel, and was shockingly close on setup. With a few changes, it will be really good. I'm going to try to get it out on asphalt ASAP with the Tamiya tires to see where it really stands, but so far, so good.

Thursday, July 21, 2011

F104X1 assembly rundown

I got a chance to work on the X1 car today and get things pretty well finished up. I have a few spots where I did some things different from the manual based on how I like to set up my current F104 for rubber tires.

I chose to use the Heavy Pivot Post as I have been using for a while. Generally, more weight is going to be helpful for rubber tire in all but the most high traction situations. As you can see I'm also not going to run any chassis posts. I feel like the car is better on bumpy tracks, as well as making more traction. One thing I did notice was that adding posts tended to tighten the car up, which sounds the opposite of taking away traction. To make a better explanation, the car would turn in but not finish the corner well. Without the posts, this went away.

Tamiya includes carbon graphite plastic parts for the pod. The parts are very light, in fact 13g vs. 26g for the aluminum pieces from the black car. They also include an aluminum motor spacer to help cool the motor. I do like the idea of saving 1/2 an ounce of unsprung weight on the pod, but for me cooling was a bigger factor. Running a silver can motor for TCS races makes the aluminum parts more desirable, knowing the motor will be running 150-160 F if everything is right. The idea of a plastic motor mount at that temperature is less than inviting. The other problem is that with a silver can, which has a very short output shaft, the pinion will not reach with the included aluminum motor spacer. I tried to attach a long shank Spec-R pinion, which I use just because the silver can shaft is short, and it still did not line up properly. I tend to think that this setup was designed more with brushless in mind.

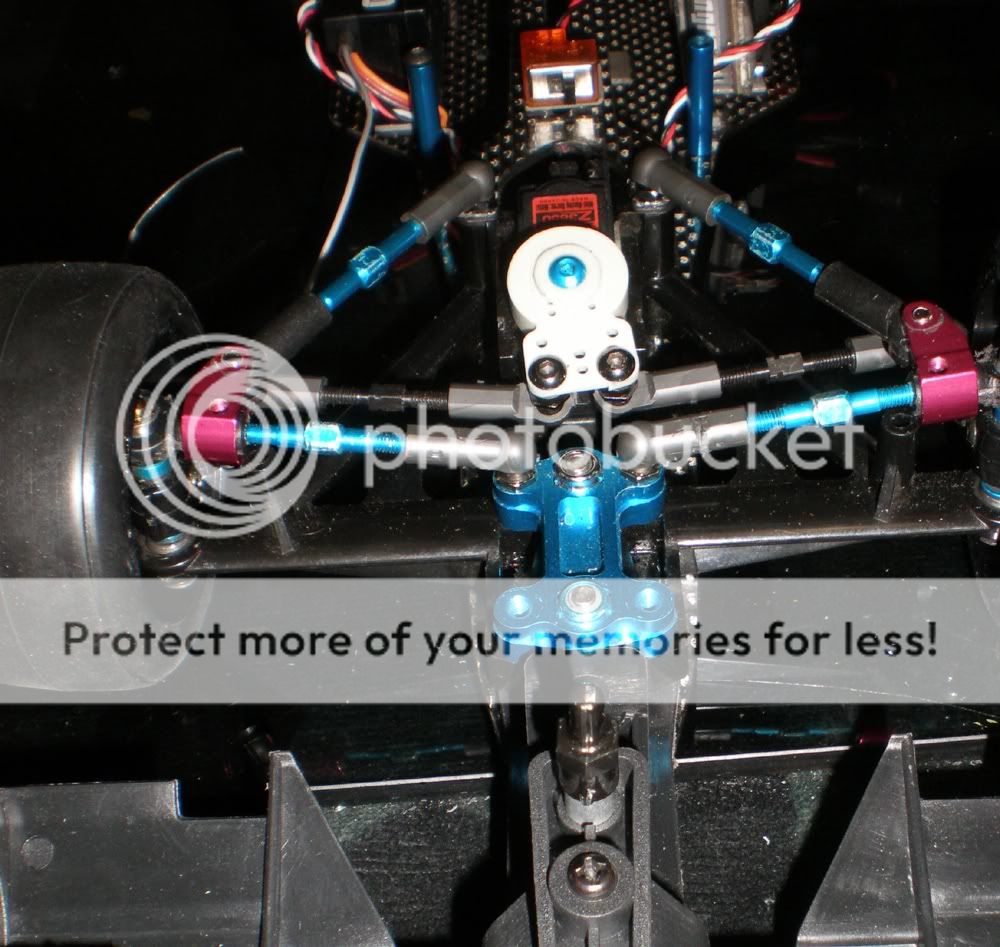

This shot has the diff as well as the side damper which is one of the new features on the car. The side damper is of high quality. It built easily and needed no extra cutting or modification. Sometimes, the dampers with 1/12 kits require you to cut or resize the damper, but this was super easy to deal with. I put 5000 wt diff oil on the damper to start, since it's really an unknown at this point. I have been running with no damper at all, and that has worked great lately. I'm excited to see how the car works with the damper affecting roll only, which is the standard in 1/12 and WGT these days.

There also are some other nice options with the car. The Short Black spring set comes with the car, so you have all three shock springs with the kit. The aluminum camber plate comes with the car as well, not to mention the aluminum servo saver horn, both in the sweet gunmetal finish.

The diff is also assembled to my preference. I like to use the one piece thrust bearing instead of the standard bearing included in the kit. The one piece is the same as the F103 thrust bearing, and it is a direct drop in replacement for the standard bearing from the kit. I think it makes the diff smoother, and it should also last about forever. Standard bearings are not meant to be used as thrust bearings....

For the diff itself, I always use Associated silicone grease. It may not be a huge deal, but I have had good success with it. In addition, I sand the diff rings with a medium paper like 400 or 600 to help give the rings some bite and create good diff action. I like to use a plastic diff hub to sand the rings in a figure 8 motion on glass or another flat surface. You can use an aluminum hub, but I have plastic ones laying around, and I don't dirty up the nice aluminum parts.

Here's a decent shot of the new counterweight setup. The counterweight rides on two normal bearings, but there is a shim with a small tab that goes between the counterweight and the bearing in the pod on the steel axle. I'm not sure if the shim is supposed to help get the counterweight spinning to provide a gyro effect or what exactly the deal is. Eventually, we'll find out at the track...

The 3.5mm offset front axle is a popular upgrade for rubber tires to make the car a bit easier to drive. One problem is that the axles come apart if the very small screw holding the metal to the plastic unscrews itself. I like to glue the axle into the plastic, and then add some glue to the screw's threads before fastening it. This has been a good method to secure things permanently!

The camber plate is also in the lowered position I prefer. There are several posts on the front end setup I like on the blog if you are interested, so I won't rehash that here.

As I said when I started the post, this is just an initial rundown on the car. The biggest changes seem to be the damper and the counterweight, and both are going to be big unknowns until I get the car to the track.

Wednesday, July 20, 2011

Monday, July 18, 2011

Randy Willard's "Vegas" edition TRG111

In anticipation of the Vegas IIC race's F1 class, this the the TRG111 of Randy Willard with some mods to make it legal for a 180mm wide "realistic" class. Mostly the front end uses F104 lower arms and mounts the TRG suspension on top, including steering arms and kingpins. Other mods include changing the rear end to a single damper tube and lowering the center shock.....

Sunday, July 17, 2011

Exotek F104 Link style front end-result

Wow, I was really happy with the this front end set up. Quite a bit had to do with the tires. I ran Pit R1-H 0572 rears and F1 0573 fronts. I had a bit of rear end hop, but I think going a step lighter on the side spring (from a CRC Red) would help that out. Otherwise, it was really good. It was easy to dial in caster and camber, and the setting held well. I started with 5* caster, but I reduced it to help get the car into the corner a bit better. Camber I set at 1.5*.

There will be a lot more testing, but I was very pleased for what was basically just a guess. Everything was really easy to work on.

There will be a lot more testing, but I was very pleased for what was basically just a guess. Everything was really easy to work on.

Exotek F104 Link style front end.

Here are a couple quick pictures of the link front end setup I made for my Exotek F104. This is the type of front end I'd like to run at the Vegas IIC race this fall. I'm not sure how everything will work yet, but it seems ok on the bench.

The red collars are Xpress RoadRunner parts. RC Mart should still have the plastic pieces available if the aluminum is not. The upper balls are from a 3Racing front end. Other than that, it's pretty simple.

Wednesday, July 13, 2011

IIC Vegas race to offer F1 class

Great News! The International Indoor Champs will offer F1 at the 2011 race.

From Scotty Ernst's Rctech post:

"The F-1 Class is definitely gaining support and it is official we WiLL be running a F-1 Class at the IIC.

I am still working out all the details and rules but it will be on Rubber Tires.

It will not be finished in time for the online Registration this Wed but you will be able to add that class when I have all the rules finished. "

"Hi Guys,

Great to read all the interest in the F-1 Class. Interest has been great since we thru the idea out. I was in Japan 2 weeks ago announcing a event and they had a F-1 Class, It flashed me back to my early days of racing in the TCS and how much fun I had with my Lotus and Sabre F-1 cars and it really got me fired up for the class at the IIC.

So it is Official! We will be running a F-1 Class at the IIC. I am working to set all the details and the rules, but it is going to happen. I will not have everything set in time for the online registration this Wed night, but you will be able to enter as soon as I have all things finalized.

Thanks to everyone for helping get the interest in the class for the IIC and keep spreading the word. Like Lightfoot said, it would be great to have a C main in this class.

Let me know if you guys have any other questions.. again, give me a chance to get all the rules and details set but it is going to rock.

F-1 at the IIC!

Game on.

Scotty"

Charles Lightfoot from the UF1 series helped to get the push started to have the class, and initial reports were that it would be based on UF1 rules for the "realistic" class - 180mm width, 21.5 motor/no boost, rubber tires.

I'll keep things updated as details come out.

From Scotty Ernst's Rctech post:

"The F-1 Class is definitely gaining support and it is official we WiLL be running a F-1 Class at the IIC.

I am still working out all the details and rules but it will be on Rubber Tires.

It will not be finished in time for the online Registration this Wed but you will be able to add that class when I have all the rules finished. "

"Hi Guys,

Great to read all the interest in the F-1 Class. Interest has been great since we thru the idea out. I was in Japan 2 weeks ago announcing a event and they had a F-1 Class, It flashed me back to my early days of racing in the TCS and how much fun I had with my Lotus and Sabre F-1 cars and it really got me fired up for the class at the IIC.

So it is Official! We will be running a F-1 Class at the IIC. I am working to set all the details and the rules, but it is going to happen. I will not have everything set in time for the online registration this Wed night, but you will be able to enter as soon as I have all things finalized.

Thanks to everyone for helping get the interest in the class for the IIC and keep spreading the word. Like Lightfoot said, it would be great to have a C main in this class.

Let me know if you guys have any other questions.. again, give me a chance to get all the rules and details set but it is going to rock.

F-1 at the IIC!

Game on.

Scotty"

Charles Lightfoot from the UF1 series helped to get the push started to have the class, and initial reports were that it would be based on UF1 rules for the "realistic" class - 180mm width, 21.5 motor/no boost, rubber tires.

I'll keep things updated as details come out.

Subscribe to:

Posts (Atom)